Structural Engineering Terminology

An explanation of some of the terms Cornell Engineers use in structural engineering:

Class M Soil

Class M soil (in Australia) is a classification that indicates a soil is Moderately responsive to changes in soil moisture conditions.

The soil reactivity classification system is defined in Australian standard AS2870.

Find out more about soil classifications in this article.

Top Plate

The piece or pieces of timber that sit on top of wall studs to make up the top of a timber frame wall.

In a timber frame wall, top plates are often 1,2 or 3 pieces of 35 x 70 MGP12 or 35 x 90 MGP12 laid on their flat side.

The top plate acts as the beam that supports the roof trusses or floor joists that sit on the wall frame.

Under wind uplift, the top plate is tied down with either steel strap (30 x 0.8 G.I. strap) or steel tie rods (M12 or M16 rods).

What is CFW in Construction?

CFW stands for continuous fillet weld.

It is an instruction to the fabricator and/or boilermaker that a fillet weld joint is required to connect two pieces of steel. The weld should be a continuous (not-ending) fillet weld.

Continuous fillet welds are used so that there is either no visible start and stops in the weld and/or so that the inside of a piece of hollow steel (like CHS) is fully sealed.

A typical specification for a CFW is 6CFW or 8CFW.

The number is the leg length of the weld and will be specified by the structural engineer based on the loads on the weld and the strength of the parent metals. (Thank you to the gent that called us up and queried whether the number is leg length or throat length because we are learning something new every day!).

We may as well make mention of the other welding term we use a lot: FSBW = Full Strength Butt Weld. We use a full-strength butt weld when maintaining the full strength of the parent steel is critical. A full-strength butt weld is more expensive to prepare and weld so obviously we only schedule a FSBW when we absolutely have to.

Trench Mesh

Trench mesh is a pre-welded mesh of steel reinforcement bars that fits neatly into a footing trench.

Typically trench mesh is set to fit neatly into a 300mm wide trench with enough concrete cover either side so that the reinforcement can be positioned well clear of the sides.

Some trench mesh sizes include:

- 3-L11TM – Three bars of 11mm diameter streel reinforcment.

- 3-L12TM – Three bars of 12mm diameter steel reinforcement.

Double Stud

Double studs” and “Triple studs” are simply 2 and 3 studs placed together to support heavy loads or to provide extra strength beside windows and doors.

G.I. Strap

G.I. Strap is galvanised iron strap. G.I. strap can be used for bracing decks and roofs or for tying down roof trusses and rafters to wall frames. It can even be used for wall bracing.

You can get galvanised iron strap from your local hardware shop in a roll. Often the strap comes pre-punched with holes for nails. Simply cut the length of strap you need from the roll. Lay it out on-site and hammer nails through the holes into the timber.

Typical strap dimensions are 30mm x 0.8mm.

MGP Timber

MGP stands for Machine Graded Pine. Sticks of timber used to be visually graded and assessed by a person that worked in the sawmill. Now a machine automatically assesses each stick of timber and allocates a grade. Standard MGP grades are MGP10 (our preference for non-structural timber), MGP12 (structural timber) and MGP15 (more expensive structural timber).

The higher the grade, the higher the strength and stiffness properties of the timber – but also the more expensive it is.

Post-Tensioned Slab

A concrete suspended slab that derives most of its strength from high tensile cables that are draped through the slab at special locations and heights. Post-tensioned slabs are used in commercial and industrial construction to reduce reinforcement, cracking, and concrete thicknesses.

Raft Slab

A footing and slab system that gains its strength from a slab with an integral perimeter edge beam and a series of internal strip footings. The strip footings are normally 300mm wide and spaced at up to 6m centres. The edge beam is normally 300mm wide and is excavated into the ground. The strength of the raft slab system comes from steel reinforcement in the edge beam, strip footings, and slab and also the depth of the beams. The depth of the edge beam (measured from the bottom of the excavation to the top of slab) gives excellent strength under the perimeter walls keys the slab into the ground. These are the main reasons we prefer raft slabs over waffle slabs.

Shrinkage Cracking

The cracks formed in fresh concrete if the water in the concrete mix evaporates before the hardening process can use it. As water leaves the concrete, the volume of the remaining concrete mix decreases leaving a smaller volume of semi-hardened concrete to fill the same space.

RHS

RHS stands for Rectangular Hollow Section (also known as rectangular box section). RHS is a hollow, rectangular cross-section structural steel beam or column. Available from Metalcorp and AustubeMills.

Steel Stud

A stud is normally one of many vertical pieces of timber or steel used in a wall frame to support the roof and internal and external cladding (the wall). Steel studs are folded light gauge galvanised steel made into a “C” shape. They generally come in 70mm high “C” shapes and 90mm high “C” shapes.

Timber Stud

(So tempted to put a picture of Brad Pitt here!) A stud is normally one of many vertical pieces of timber or steel used in a wall frame to support the roof and internal and external cladding (the wall). Timber studs are normally softwood timber measuring 70mm x 35mm or 70mm x 45mm or 90mm x 35mm but hardwood timber can also be used.

We prefer using MGP12 softwood but sometimes use MGP15 for heavy loads. We prefer to use MGP10 timber for non-loadbearing walls unless material shortages force us to use it.

Truss Tie Down

More common in cyclonic areas, roof trusses need to be fixed to wall frames with straps or brackets to prevent roofs from lifting off in a cyclone.

Waffle slab (Also known as Waffle Raft)

A waffle slab is constructed on top of firm, flat ground by forming the perimeter with conventional formwork and the internal strip footings with polystyrene void formers. The internal strips of concrete are normally about 110mm wide and are about 1000mm apart. The strength of the waffle slab comes from reinforcement in the bottom of the internal strip footings and the 300mm wide perimeter edge beam (bottom reinforcement) and mesh reinforcement in the slab (top reinforcement) . Extra strength is achieved by increasing the height of the slab above the ground with resultant deeper internal strip footings and edge beams. The advantages of waffle slabs are they are quick and easy to construct. The disadvantages of waffle slabs are that they rely on the ground staying firm and flat (and dry) for the best performance.

Abelflex

Abelflex is a foam filler that comes in a roll. It is normally 10mm thick and has one side that is sticky. The primary purpose of Abelflex is to create an isolation space in concrete. it might be used to keep a pathway (10mm) away from a house slab or to create a gap around a pipe that passes through a footing. We have an article on Abelflex that you might like to read.

Duragal Steel

Duragal is a brand name for a range pre-galvanised steel poles/stumps/columns/posts. Normally hollow and square, rectangular or circular in section, DuraGal is a great product for posts under your house, in your walls, or in your patio.

Depending on the location of your building, the DuraGal might need extra corrosion protection. Ask your engineer.

We also wrote an article about DuraGal that you might like to read.

In Construction What is a Purlin?

A purlin is a roof member much like a rafter except that purlins run directly under roof cladding without roof battens.

The spacing of purlins is selected based on the loads, the capacity of the roof cladding to span between supports, and the capacity of the purlin to span between walls, beams, or rafters.

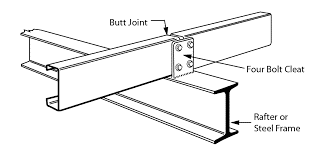

8 Pl Cleats

This one is by request from Dion in the comments.

Pl stands for “plate” so when written out in full it becomes:

8 plate cleats.

An 8 plate cleat is 8mm thick steel plate welded to a steel beam and is used to bolt steel purlins or girts to the beam.

In Construction What is a Stringer?

A stringer is a structural beam that supports the treads of a stair. It often spans from one floor level up to the next.

In Construction What is an RFI?

RFI stands for Request For Information. In large construction projects where tight documentation control is needed but some information is missing on the drawings, the builder issues an RFI to the architect or engineer or designer and receives a written answer that is kept in an RFI register.

What is Formwork?

Formwork is the temporary timber or steel framing used to support new concrete construction until the concrete is poured and cured. Formwork often comprises props, scaffolding, joists, bearers and form boards.

In Construction What is Flashing?

Flashing is the sheet metal that is bent and placed by roofers to seal a roof at the cut ends of roof sheeting. For example flashing is placed at the apex of a roof where the roofing sheets intersect. Flashing is also used at penetrations through the roof sheeting such as at vent pipes and air-conditioner penetrations. Flashing is installed straight after the roof sheeting is installed.

Slab on Grade

Slab on grade is a concrete slab poured straight on the ground whether it is natural ground or imported fill. The main two types of slab on grade that you might hear about are waffle slabs and raft slabs.

A waffle slab sits entirely on top of the ground.

A raft slab has at least the perimeter footings and sometimes the internal footings dug into the ground.

Which grade of concrete is used for slabs?

In Australia N20 and N25 grade concrete is used for residential slab construction. N25, N32 and N40 concrete is used for industrial and commercial slabs depending on the loads, surface strength and flexural capacity required. Your engineer will specify what minimum grade of concrete you should be using. You can, of course, use higher grades of concrete than specified without asking.

Can I add water to the concrete when pouring a structural slab?

No.

Adding water to the concrete in a premix truck will have one positive effect – it will make the concrete easier to pour and screed.

However adding water to concrete has many negative effects:

- the concrete surface will be less durable and more likely to ‘dust’ ie the slab will seem dusty every time you sweep it.

- the strength of the concrete will be less than specified and ordered.

- the concrete is more likely to have shrinkage cracks when it dries.

What is Repointing brickwork?

The mortar lines between bricks sometimes break down due to weather or crack due to house movement. Repointing brickwork is the process of removing the external, visible portion of the mortar (with a grinder) and replacing it with fresh, uncracked mortar.

Yes. You can repoint brickwork yourself but this job is normally undertaken by a qualified bricklayer. They have the tools and experience required to repoint brickwork.

What is a hydro-static test of sewer pipework?

A hydrostatic test (or more correctly a sewer flood test) is the best test for determining if you have any leaks or breaks in your sewer pipework.

I liken the test to filling up a bucket of water and watching to see if the water level drops. If the water level drops you know you have a leak in the bucket. Now you just have to find it and repair it.

We prefer sewer flood tests over camera inspections of pipework as an initial test. I think a camera inspection of pipework is like sticking your head in a bucket of water to look for a leak – a flood test is so much easier and more accurate.

Once you know you have a leak in your pipework then you can use a camera test to find the leak.

9 replies on “Structural Engineering Terminology”

Hi,

I believe there are two types of concrete floors which a structural and non structural in bathrooms.

How could you determine it prior to demolition, cutting or grinding?

Is there any method to find it out without making any damages?

Thank you for your time!

Hi, I have a question about welding.

I got a description of: 4mm CFW x 1000mm (250 runs).

What does the runs stand for and would this affect the pricing of welding.

Thanks

Hi Imad

The “runs” are the lengths of the weld (ie 4 x 250mm = 1000mm). Yes it will affect the price of the welding – the more welding required the more the cost.

Matt Cornell

8PL cleats!!! I cannot find a definition for this spec.

What did we miss? Comment with a structural engineering term that we missed and we’ll add it to our website.

You mention the MGP 10 is non- structural, when in fact this is not the case. MGP10 well and truly meets Australian standards and the NCC for structural timber

Hi Craig

Thanks for stopping by. You are correct. MGP10 can be used for structural applications and due to material shortages, it is being used more and more. There are tables for it, it can be used legally as structural timber and so long as the sticks of timber are straight, there is really nothing wrong with it. And yet, as engineers specifying timber for homes, we still prefer and will continue to specify MGP12 over MGP10 for structural external loadbearing walls. We’ll just use MGP10 for the internal nonloadbearing walls where possible.

Old habits die hard.

Matt Cornell

Informative one @

Thank you for your feedback. Have a great day!